Airlift Pumps

Airlift pumps are a simple and reliable mechanical solution for water and wastewater treatment applications. Suitable for pumping a range of wastewaters, they can be used in any pumping scheme where lifts of 1.5 m (5 ft) or less are required.

They have no moving parts, seals, or electrical equipment, making them highly resistant to clogging. They are simple and reliable, with minimal operating and maintenance (O&M) costs for a long service life in water & wastewater treatment plants.

Contact an ExpertConventional pumping systems typically feature mechanical equipment and can easily clog or be damaged depending on the management of grit and screenings. Pumps that become damaged or require significant maintenance downtime can compromise treatment objectives and result in increased O&M costs of water and wastewater treatment plants.

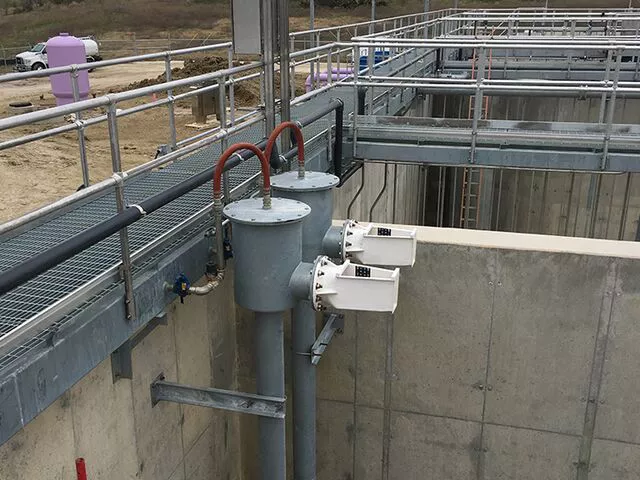

Ovivo’s Airlift pumps help reduce downtime and maintenance costs, and increases the overall reliability of the system as they have no moving parts, seals or electrical equipment. No special housings or protection measures are required.

Airlift pumps are available in a range of sizes. They are designed to suit all applications and can fit into any wastewater pumping scheme where lifts of 4 to 5 ft (1.3 to 1.5 m) or less are required. They are ideal for pumping chemical floc, raw sewage, grit, primary sludge, return activated sludge, and mixed liquor.

Airlift pumps use low air pressure to pump liquid, which makes them energy efficient and cost-effective to operate. Airlift pumps provide many other operational advantages over conventional pumping systems, such as:

- Minimum maintenance operation

- Installation simplicity

- Control simplicity

- Long Service Life (up to 20 years, which is the typical life of a wastewater treatment plant)

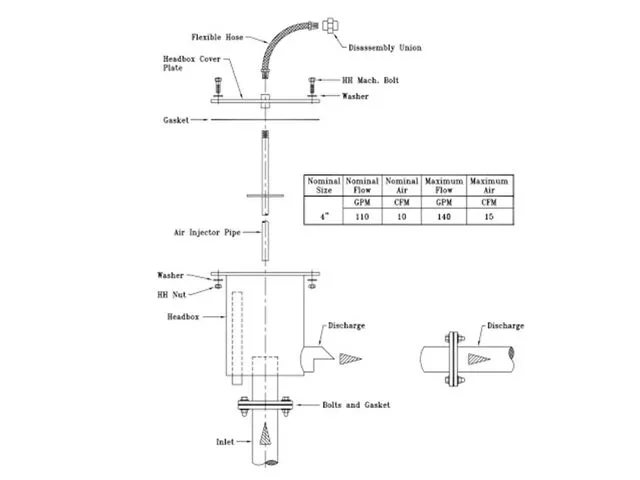

An airlift pump uses air to move liquid. It consists of a pipe that is partially submerged in the liquid to be pumped. Air is injected below the surface of the liquid and create air bubbles that mixes with the liquid, creating a mixture that is less dense than the liquid surrounding it. This causes the liquid to flow into the pipe and be displaced upwards, like water being sucked up a straw. The air and liquid mixture is then pushed out of the top of the pipe and into the discharge.

A plug valve in the airflow line controls the flow of the pumps. For automatic control, a solenoid is added to the air line. Motor starters, VFDs, sequencers, etc. are not required. The simple control schematics take advantage of a wide variety of conventional or solid-state circuitry.