AnammoPAQ®

An innovative deammonification process that uses Anammox® bacteria and ammonia oxidizing bacteria (AOBs) to treat high nitrogen sidestream flow in wastewater treatment. It’s ideal to place after the dewatering process for an anaerobic digestion process.

An innovative deammonification process that uses Anammox® bacteria and ammonia oxidizing bacteria (AOBs) to treat high nitrogen sidestream flow in wastewater treatment. It’s ideal to place after the dewatering process for an anaerobic digestion process.

Contact an ExpertAnammoPAQ technology offers a range of features and benefits that make it a unique and innovative solution for deammonification in wastewater treatment. One of its key characteristics is its compact granular system, which contains both Anammox (anaerobic ammonium oxidation) bacteria and AOBs that coexist in one granule to convert ammonium into nitrite (NO2) and then into nitrogen gas. This process significantly reduces oxygen in comparison to conventional nitrification, eliminates the need for an external carbon source, and reduces overall sludge production.

The complete granular sludge nature of the AnammoPAQ process allows for superior loading rates application, thereby significantly reducing process footprint and energy demand. This in turn, further optimises nutrient management and reduces overall plant operating and maintenance costs.

Key features and benefits of the AnammoPAQ system includes:

- Compact footprint due to high loading rates

- Low project costs

- Low operating and maintenance costs

- Significantly lower energy costs for ammonia removal

- Stable and robust process

- High experience and large reference base

- Quick startup

Downloadable Resources

The AnammoPAQ process is an elegant shortcut in the natural nitrogen cycle, as it directly converts ammonium into nitrite and nitrogen gas. It utilises a granular system that contains both Anammox bacteria and AOBs (ammonia oxidizing bacteria) that coexist in one granule. This system allows for simultaneous nitritation and Anammox conversion to occur in a single process unit, reducing the need for oxygen, eliminating the need for an external carbon source and reducing overall sludge production.

The Optimal process control ensures retention of AOBs and Anammox bacteria while eliminating NOBs, leading to stable and robust operation.

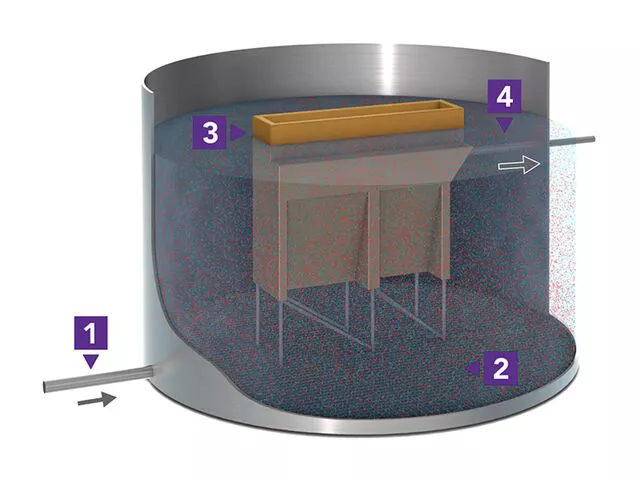

The process flow in the diagram is as follows:

- Ammonia-rich influent

- Aerators for mixing and ammonia removal process

- AnammoPAQ separator for biomass retention

- Effluent exits the reactor

The process stoichiometry is detailed below:

The AOB facilitates the first reaction:

NH4+ + 1½ O2 to NO2– + H2O + 2H+

The anammox bacteria facilitates the second reaction:

NH4+ + NO2– to N2 + 2H2O

Anammox® is a registered trademark of Paques BV