DigestivorePAD™ Process

A biosolids management solution that helps wastewater treatment facilities meet effluent limits by reducing nitrogen in the sidestream & sludge management costs through improved volatile solids reduction (VSR). It also provides struvite stabilisation and improved odour control.

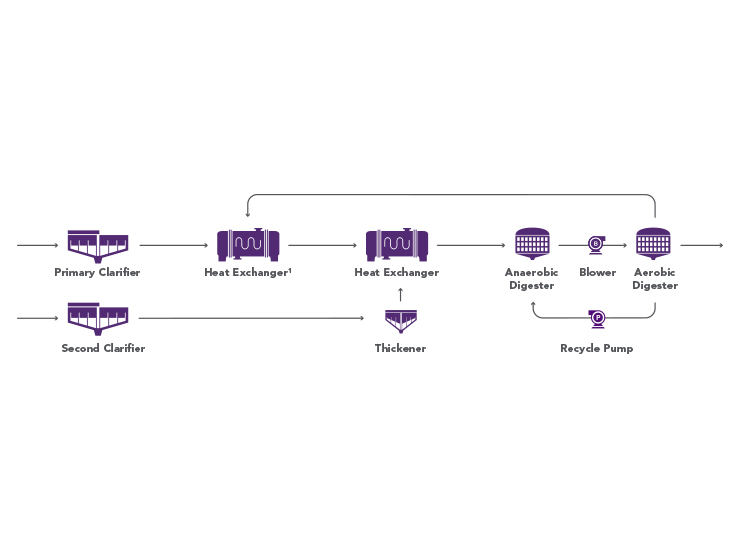

The DigestivorePAD process integrates an aerobic digestion step after an anaerobic digestion to reduce nitrogen levels, prevent struvite scaling, and minimise sludge disposal.

Contact an ExpertThe DigestivorePAD Process is an advanced sludge treatment technology for wastewater treatment. It helps facilities meet their effluent limits by reducing nitrogen in the sidestream flow through the use of an aerobic digestion step after the anaerobic digestion, which achieves nitrification and denitrification. It also provides additional VSR, reducing disposal costs significantly. The DigestivorePAD process can be retrofitted into existing sludge storage tanks, saving on capital and installation costs. Additionally, it stabilises struvite, providing cost savings for operation and maintenance.

A simple biosolids management solution that offers a comprehensive range of benefits

Benefits of the DigestivorePAD process include:

- Ammonia reduction by approximately 80 percent in the side stream

- 10 to 30 percent additional VSR

- Struvite stabilisation

- Minimise nuisance odours

- Potential improvement of dewatering

- Ideal for retrofitting in existing tanks

Downloadable Resources

The DigestivorePAD process helps manage the solid waste produced at wastewater treatment facilities. It consists in breaking down the solid waste in two stages with an internal recycle:

- The anaerobic digestion stage, which is a process that occurs without oxygen.

- The aerobic digestion stage, which is a process that occurs with oxygen.

By adding the second step, the DigestivorePAD process is able to break down the solid waste even further, reducing its volume and improving its quality.

Studies have shown that certain organic compounds in sludge digestion can only be degraded under anaerobic or aerobic conditions. The DigestivorePAD process combines both, providing an additional mechanism for VSR of up to 30 percent. The additional organic reduction will also improve the dewaterability of biosolids.

The DigestivorePAD process can achieve both aerobic and anoxic reactions inside the reactor. This facilitates nitrification and denitrification processes, resulting in total nitrogen removal. As the aerobic treatment removes up to 80 percent of ammonia, odours are significantly reduced.

The DigestivorePAD reduces the chance of struvite scaling in process piping and on dewatering equipment. This is achieved by removing ammonium which is a key component required for struvite formation. Furthermore, the post aerobic digestion step (also called PAD) strips CO2 out of sludge and stabilises pH so that any possible struvite formed remains in the sludge (solid phase). This also results in significantly reduced phosphorus levels in the side stream (liquid phase).