For Granular Media Filtration and Backwash Distribution

FlexKleen® nozzles

While conventional methods of controlling head loss can lead to a reduction of filter material and require frequent cleaning intervals, FlexKleen nozzles are engineered to maintain clear orifice openings, minimising the head loss necessary for process requirements.

FlexKleen nozzles are suitable in heavy industrial waste applications and potable water treatment as well as in any type of pressure or gravity filter, including steel or concrete filter floors, and with sand, anthracite and granular activated carbon media.

Contact an ExpertFlexKleen nozzles have a number of design features that make them an industry-leading product, such as:

- The improved FlexKleen nozzle heads are injection moulded from strong, chemical resistant acrylonitrile-butadiene styrene (ABS) plastic. Other plastics are available for special applications.

- Most granular media filters are designed to end the filtration cycle at maximum differential pressures of 2 to 10 psi across the media. However, chance malfunctions or operator errors have the potential to allow differential pressures to approach the structural ratings of the filter tank. FlexKleen nozzles are rated for 20 psi pressure drops. Laboratory tests simulating a 20-year period of two cycles per day indicated that the nozzles will survive repeated abuse at multiples of rated pressure, ensuring a long product life.

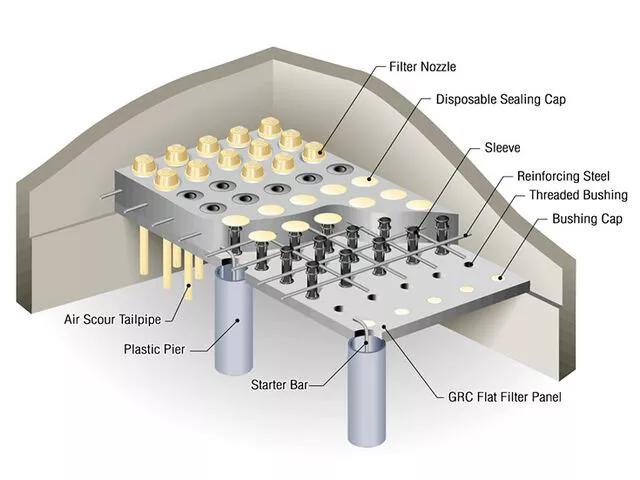

Our underdrain nozzles are designed to carry out 4 basic functions:

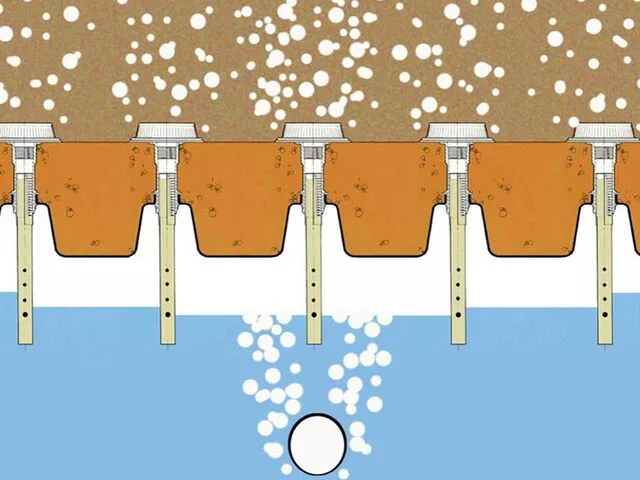

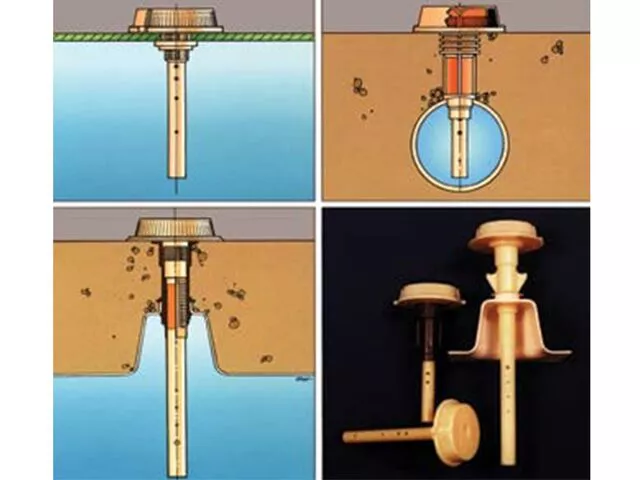

- Uniform distribution of water distribution. The pressure drop created in the nozzles ensure water backwashing is evenly distributed through the filter media. Water is discharged radially at a 15-degree angle above the filter floor. An internal cone directs and stabilises flow inside the nozzle head.

- Elimination of gravel layers. Vertical ribs in the nozzle head prevent filter media from passing into the plenum chamber. Slots widen towards the inside, presenting a sharp outer edge to the media. This allows the placement of sand directly onto the nozzles, eliminating gravel layers and their associated problems.

- Uniform distribution of air scour. Backwash air is metered evenly into all nozzle heads through air tubes. Multiple orifice sizes and elevations are optimised for low, medium or high-rate air scour requirements. A baffle ring extending down from inside the top of the nozzle directs the scouring force of the air in a radical pattern from each nozzle.

- Elimination of internal pressure balanced feed distributors. The pressure drop created by the nozzles balances the collection of filtrate during the filtration cycle, eliminating the need for a header and lateral type filter inlet distributor