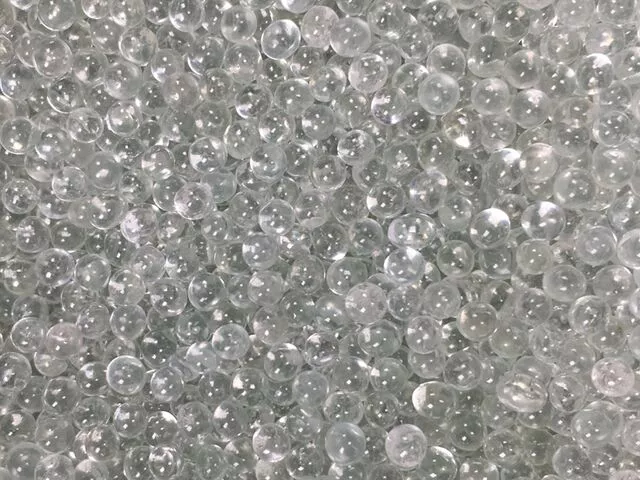

Glass Beads

Glass Beads represent a significant advancement in raw water filtration compared to conventional sand and gravel filtration systems. This innovative, high-performance technology can improve both the quality and volume of filtrate.

While Glass Beads are used in the same way as sand or gravel, they are far superior in their purity, strength and longevity. Glass Beads can be used to treat water and improve efficiency at both new and existing plants, enabling our partners to reduce costs.

Contact an ExpertGlass Beads offer considerable benefits starting with significant improvement in filtration. This innovative technology is also able to increase the workload capacity and reduce backwash frequency and duration, as well as substantially reduce investment and running costs.

Other important features and benefits include:

- Reduced footprint by up to 40 percent

- Up to 30 percent less backwash water

- 80 percent reduced backwash duration, less downtime and pumping energy

- Up to 50 percent increase in filtration time between cycles

- Smooth surface (no porosity), resulting in very low risk of biofouling

- 10 times higher crushing strength than gravel

- No contamination, no special preparation needed

- Conditioning or recycling possible

- Substantial reduction in investment and running costs

A revolutionary filtration media

Glass Beads have a crushing strength that is 10 times greater than sand or gravel, which makes them much more resilient than conventional filtration media. In fact, if used properly, Glass Beads have no lifetime limits and there is no need for special routine checks during use, apart from the mandatory process or system checks.

Four different grades of Glass Beads are available, ranging in size from 0.25 mm to 4 mm (60 to 5 mesh). The grades used in the filter bed layout depends on the requirements of the particular application. Various parameters, such as raw water quality, desired or required filtrate quality, flow rate, filter speed and other factors are all taken into account. An application-specific filter bed is carried out by Ovivo’s experienced process engineers.

Glass Beads are ideal for new plants, but this high-performance filter media can also be retrofitted to existing plants. This system is capable of operating in a much-reduced footprint, compared to conventional systems, because of its filtration efficiency.

Polished Glass Beads are made of soda lime glass, which is more durable and has a higher density than conventional filtration media, which consists of natural sand and gravel. Quartz sand has a density of 1.2 kg/l (75 lb/ft3) while Glass Beads ranges from 1.46 to 1.53 kg/l (91 to 96 lb/ft3) depending on the size of the Glass Beads.

Glass Beads are packed in standard 20 kg (44 lb) bags or in big bags, 1,000 kg (2,205 lb). Each bag is labeled with article, diameter, lot # and quantity. They are sensitive to high temperature deviations and must be stored in a cool dry area and kept in its original packaging until use.

Glass Beads are delivered from the factory in a pure and clean condition, so no special preparation or conditioning is necessary before use. In contrast, dust and debris can be found in sand and gravel, which might contaminate the system, and must therefore be thoroughly conditioned prior to use.

Filtration with Glass Beads technology offers considerable benefits with significant improvement in filtration:

- 90 to 95 percent rejection down to 1μm particles

- 42 percent higher interstitial space volume for maximum dirt holding capacity

- A 25 percent capacity gain in treated process water is realized, on average, compared to raw water filtered volumes between each backwash with conventional multimedia filters

For additional information download the Technical Data Sheet.