Mixed Bed Ion Exchange

Mixed bed ion exchange is used to economically produce demineralised water for a wide variety of applications, such as final polishing, located downstream of a primary demineralisation stage, or polishing high purity water recycle loops and condensate polishing.

The collection systems within internally regenerated mixed beds are a common failure point. Our internally regenerated mixed bed systems offer a robust solution capable of withstanding the forces that are imposed during service and regeneration cycles, providing long term reliable operation.

Contact an ExpertMixed beds, also known as mixed bed ion exchange, efficiently remove dissolved minerals to provide water that has a conductivity of less than 0.06 µS/cm. Our unique water distribution systems, developed for high velocity polishing applications, allow operation at high resin bed velocities without swirling of the resin within the vessel.

Mixed beds have a robust internal distribution system that is effective in even the most demanding applications around the world. Our mixed beds are installed in industrial applications including nuclear and supercritical power stations. They operate at high pressures and velocities where maintaining water quality and reliability is essential for efficient power generation.

Flexible mixed bed ion exchange solutions

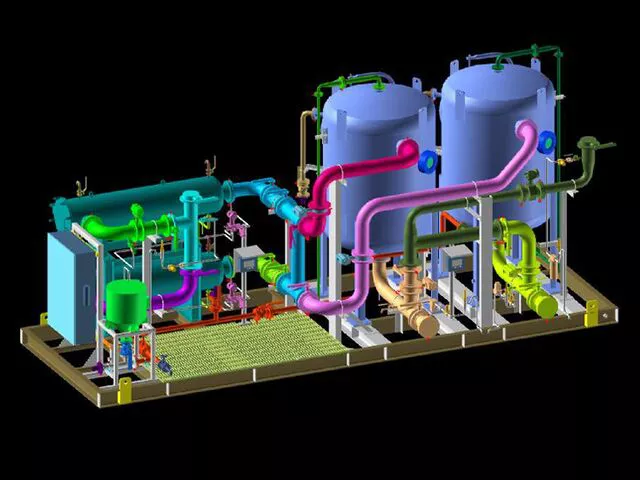

Mixed bed ion exchange systems can be used as a solution for a wide variety of industrial applications, where high purity demineralised water is required. Our systems are designed to be water and chemical efficient reducing operating costs and providing a sustainable solution. We can supply Mixed Beds ion exchange systems as a pre-engineered plant to Ovivo specifications or customised to your specifications.

Mixed beds have a range of benefits that put this product ahead of the competition, including:

- Uniform flow distribution to maximise resin capacity

- Proven robust design maximising availability

- Fully automated operation

- High velocity design to minimise footprint

- Offsite or onsite resin regeneration

Downloadable Resources

Mixed bed polishing is an ion exchange-based water treatment technology that comprises of a bed of cation and anion resins, intimately mixed and housed within a cylindrical vessel. The mix of resins provides a perfect environment for the removal of dissolved ionic contaminants.

Mixed beds can be supplied as internally regenerated where the resin is separated around a central collection system within the vessel. The separated resins are then individually regenerated with the appropriate chemical, rinsed, mixed using air and then returned to service. We also offer externally regenerated systems, such as our Conesep® and Movex® products, where the resin is transferred from the vessel to an external regeneration system for the condensate polishing process.

Where mixed beds are acting as a final polisher step in a high-purity demineralisation system, a non-regenerable mixed bed polisher can be a more cost-effective solution. Ovivo offers a service option to remove the resins and regenerate off-site for return and reuse where appropriate, eliminating the need for on-site storage and handling of chemicals for regeneration.

Where mixed beds are acting as a final polisher step in a high-purity demineralisation system, a non-regenerable mixed bed polisher can be a more cost effective solution. Ovivo offers a service option to remove the resins and regenerate off-site for return and reuse where appropriate, avoiding the customer the need to handle and store chemicals on site for regeneration.

Mixed bed systems offer a range of technical features and benefits, including:

- Compliance with EPRI and VGB requirements

- Treating a wide range of flows and pressures to meet site specific conditions

- Modular skidded designs

- opsCNTRLTM enabled to allow remote digital monitoring and diagnostics from mobile phone, tablet or PC

- Feed studies

- Life cycle cost analysis

- Full design build support

- Process optimisation

- Refurbishments and upgrades