Electro Deionisation

Electro Deionisation (EDI) is a polishing step to remove low levels of dissolved contaminants from water, such as reverse osmosis permeate. Producing high purity demineralised water, similar in quality to that of a polishing mixed bed ion exchanger, but without the need for chemical regenerants.

Ovivo EDI solutions are a sustainable chemical-free system designed to match your specific water polishing application. Capable of treating a variety of flows, with options to match your water quality needs.

Ovivo EDI systems are ideal for a variety of industrial applications, where high purity water is required. They can be supplied in a standard, pre-engineered format or custom-built to your specifications. Our EDI systems have numerous important features and benefits, including:

- Wide range of EDI modules for different flows and qualities

- Compact footprint compared to ion exchange systems

- Robust proven designs maximising availability

- Fully automated for operation on unoccupied sites

- Chemical-free high purity water with a low carbon foot print

What does Electro Deionisation remove from wastewater?

Electro Deionisation technology is utilized to remove any ionizable contaminants from water utilizing active media and an electric current. More specifically, EDI can remove ion and mineral substances like sodium, chlorides, sulfates, and a variety of others. In some cases, EDI is also utilized in removing certain organic compounds, although not typically the main tool featured in this process.

Generally, Electro Deionisation is used in combination with a selection of other treatment, like reverse osmosis and cartridge filtration systems. This produces highly pure water that is required in a variety of electronics manufacturing processes.

An efficient chemical-free demineralisation solution

EDI is a sustainable technology that utilises electricity and ion exchange resins to produce high purity demineralised water without the use of bulk chemicals. Our EDI systems are engineered to be water efficient and the reject water stream can often be returned further up the process, minimising water consumption.

Electro Deionisation

EDI is a simple and highly effective demineralised water polishing technology that uses a combination of interspersed ion selective membranes and ion exchange resins. As water passes through the ion exchange resin in the feed compartments, the dissolved contaminants are exchanged for hydrogen or hydroxide ions, producing high purity water.

A direct electrical current (DC) is applied across the module of ion exchange resins and ion selective membranes causing the removed contaminants to migrate across the resin and become trapped in the concentrate chambers formed by the ion selective membranes. The captured impurities then flow out with the concentrate stream.

Ovivo EDI systems offer a range of technical features and benefits including:

- High water efficiency

- High purity water without the use of chemicals

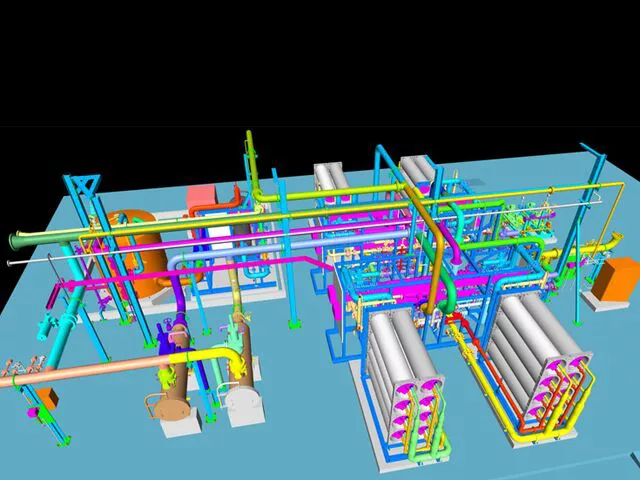

- Modular skidded design or mobile containerised units

- opsCTRL™ enabled to allow remote digital monitoring and diagnostics from mobile phone, tablet or PC

Our Ovivo team works closely with all partners to assist with their water purification needs by providing:

- Feed studies

- Life cycle cost analysis

- Full design build support

- Process optimisation

- Refurbishments and upgrades