Brackett Green® StopGateTM

The Brackett Green StopGate provides a means to isolate flow streams, ensuring safe and dry access for routine maintenance on downstream screening equipment and pump intakes.

This customisable nature of the Brackett Green StopGate, and its modular design, makes it suitable for a wide range of applications. The system also has numerous additional features that facilitate use, including lifting beams and storage supports.

The Brackett Green StopGate can be designed to withstand seismic and hydraulic loads, and is seismically qualified for nuclear power applications. The customisable design means it can fit any size channel, as well as enabling sealing under high differential, in either single or dual direction. The modular construction makes it possible to locate one module on top of the other, enabling isolation of large openings, whilst maintaining safe handling of the smaller sections of gate.

The unique cill sensing device is incorporated in to the StopGate technology to facilitate automatic release and recovery when the StopGate section is being installed or removed from the channel or storage location. Each StopGate module is fitted with valves, enabling the isolated chamber to be flooded, allowing the water to equalise prior to gate removal.

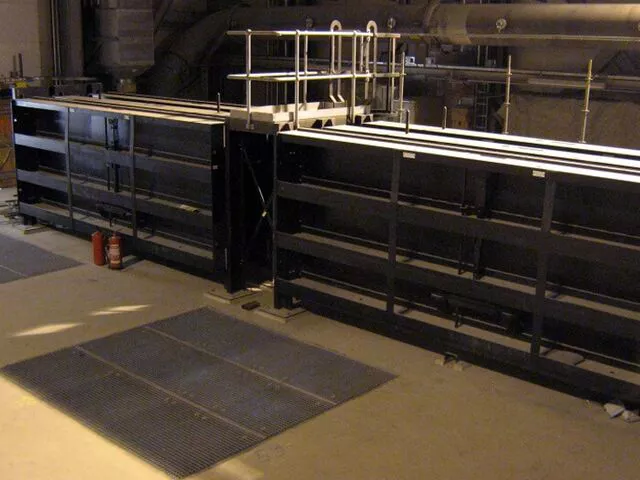

Ovivo also provides a purpose designed lifting beam to ensure safe handling during operation. The Ovivo Storage Rack supports the gates when not in use, to minimise the risk of seal and paint damage and to prolong the operational life of the product.

A fully customisable solution

The Brackett Green StopGate is fully customisable and offers a range of benefits that put this product ahead of the competition, such as:

- Ability to maintain operability during and after high load applications, such as high differential or seismic events.

- Ability to stack one module on top of the other, enabling isolation of the channel to be extended above the highest water level. This arrangement removes the need for a concrete apron wall.

- Epoxy coated as standard, and supplemented by sacrificial anodes where required.

- Customisable lifting beam to ensure safe handling of the StopGate.

Safe Channel Isolation

When installed in the chamber the Brackett Green StopGate module is located within stainless steel guides embedded in the civil structure. These guides, together with the cill and lintel, provide a sealing face for the neoprene seals, enabling the downstream chamber to be drained and allowing safe maintenance of downstream equipment.

Upon completion of the work, the lifting beam is re-engaged and the StopGate is removed and placed in the storage rack. The initial lift opens the valves without raising the gate and allows water to pass through each module to equalize the pressure on both sides. Once equalization is achieved, the gate can be safely removed. A unique cill sensing device is incorporated to prevent accidental release of the lifting beam in the event of modules jamming in the guides while being lowered.

The Brackett Green StopGate has been successfully installed in hundreds of applications worldwide. The current design, which has been refined through years of experience, has the following technical details:

- Channel widths of up to 6 m (8.2 ft) and individual module heights of 4 m (13 ft).

- Operability during and after high load applications, such as high differential or seismic events.

- A fully customisable range of materials.

- Ovivo Lifting Beam to ensure safe handling.

- Customised storage in either deck-mounted or pit-assembled racks.