M-TAD™ Process

The Mechanical Thickened Aerobic Digestion (M-TAD™) process is a controlled aerobic process engineered and designed to meet Class B stabilisation requirements by integrating system optimisation techniques and making use of a unique non-clog single drop diffuser system.

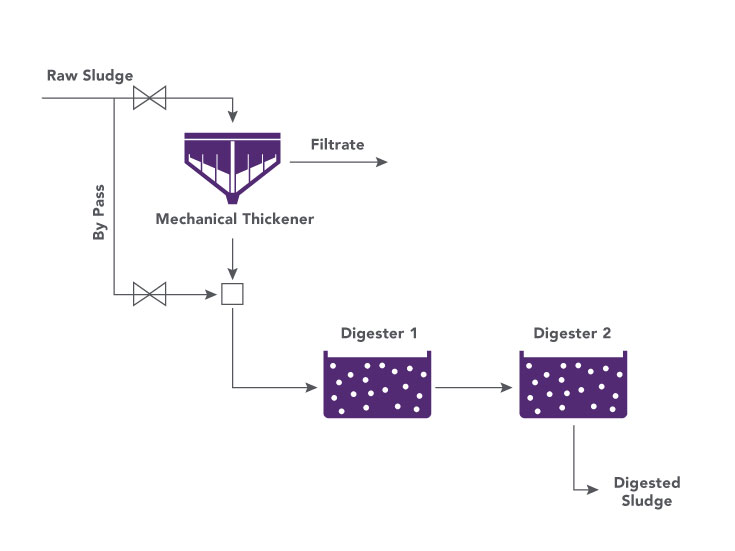

The M-TAD™ process utilises a mechanical thickener to thicken solids up to 4 percent which significantly reduces aerobic digestion volume and footprint. This process can also be retrofitted into existing tanks.

Contact an ExpertWith more than 30 billion gallons of wastewater being treated in 16,000 facilities every day in the United States, biosolids management is a serious issue in municipal wastewater treatment. It is responsible for between 30 and 60 percent of operating and maintenance expenses.

Ovivo’s M-TAD™ process solution is ideal for both new plants and existing plants looking to retrofit. These systems also allow plants to maintain the industry standard of using solids in land applications instead of just disposing to landfills.

Expand your system’s ability with minimal cost and effort

Ovivo’s M-TAD™ process combine sludge thickening and controlled aerobic digestion into one seamless operation, dramatically improving your plants treatment ability to efficiently manage biosolids while reducing daily operating and maintenance costs. The features and benefits of these solutions include:

- Class B biosolids stabilisation

- Minimised footprint

- Ideal for converting anaerobic to aerobic digestion process

- Easy retrofit technology

- Minimal nutrients returned to the upstream liquid treatment process

- Reduced operating and disposal costs

The M-Tad process is a controlled aerobic digestion process that utilises a mechanical thickener and a minimum of two aerobic digesters combined with a membrane thickener (MBT) and optional anoxic basin. Waste Activated Sludge (WAS) is pumped into the MBT and permeate is extracted through the membranes with a low suction pump. A mechanical thickener then thickens the sludge up to 4 percent solids. Once thickened, the sludge passes through the aerobic digesters that operate in series. The first stage digester forms a recycle loop with the MBT and optional anoxic basin that allows the digested sludge to be continuously thickened while undergoing both nitrification and denitrification. This is where the majority of the volatile solids reduction (VSR) occurs. When the maximum liquid level in the In-Loop Digester is reached, the addition of sludge to this tank will cause a corresponding overflow of sludge to the second stage tanks where the sludge remains until it meets pathogen removal required for class B compliance. The sludge is then transferred out of to be dewatered or for final disposal.