Gas Moisture Removal

Ensure a safe working environment and optimise biogas production with gas control drip traps. Drip traps safely collect and remove condensation, either manually or automatically, from gas pipe systems.

The biogas produced within the digester creates enough pressure to move through the piping system to reach boilers, generators, or gas holders. Drip traps are installed at all low points of the pipe system to drain condensation and sediment to protect downstream equipment from corrosion, clogging, or water hammer.

Biogas is generated during the anaerobic digestion process and is an energy source that can be captured and used in various ways or safely burned. It’s a highly moist mixture of gases, consisting of methane (CH4), carbon dioxide (CO2), and trace amounts of nitrogen (N) and hydrogen sulphide (H2S).

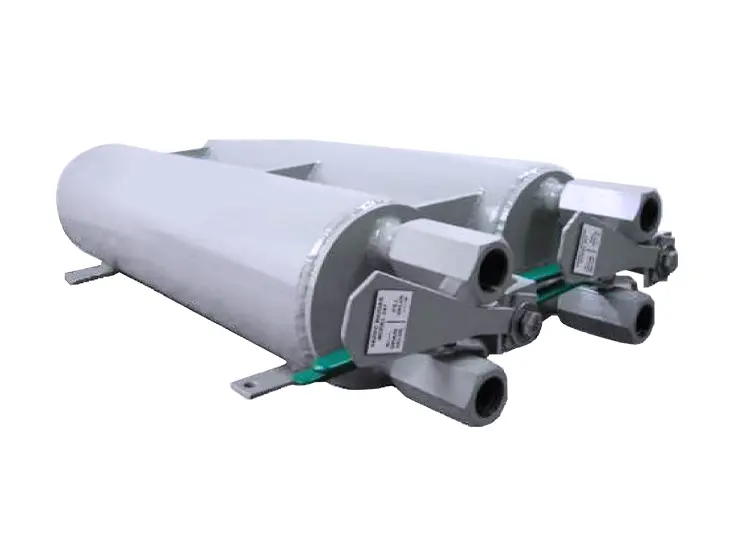

The 233-Series Condensate and Sediment Trap is designed to be installed immediately downstream from each digester. It is used to remove the large volume of condensed water created when the gas cools as it exits the digester with a maximum working pressure of 25 psig (172.5 kPa). It will also accumulate any sediment that was entrained in the gas and can be installed in other locations where large volumes of water must be removed from the gas system.

How It Works

As the biogas enters the trap, a sharp drop in velocity and centrifugal force allows condensate and sediment to be removed automatically as gas flows through. Storage capacity is a minimum of six gallons sediment and six gallons condensate. A large, 2-inch blowout and drain connection allow accumulated sediment to be easily cleaned from the trap.

Design Features

- Welded steel construction

- Galvanised finish, epoxy coated internals, stainless steel option

- Easily cleaned

Downloadable Resources

Designed for continuous collection and safe removal of condensate, the 245 Series Automatic Drip Trap is intended only for ‘’filtered’’ gas service with maximum working pressure of 25 psig (172.5 kPa).

How it works

Utilising a float operated needle valve, the unit automatically drains the condensate. As condensate accumulates in the drip trap reservoir, it lifts the float that’s connected to a lever arm that operates the needle valve. The float is positioned within the reservoir so that the needle valve closes when the liquid level is still above the outlet port.

Design Features

- Corrosion resistant aluminium construction

- 2 Quart Capacity

Downloadable Resources

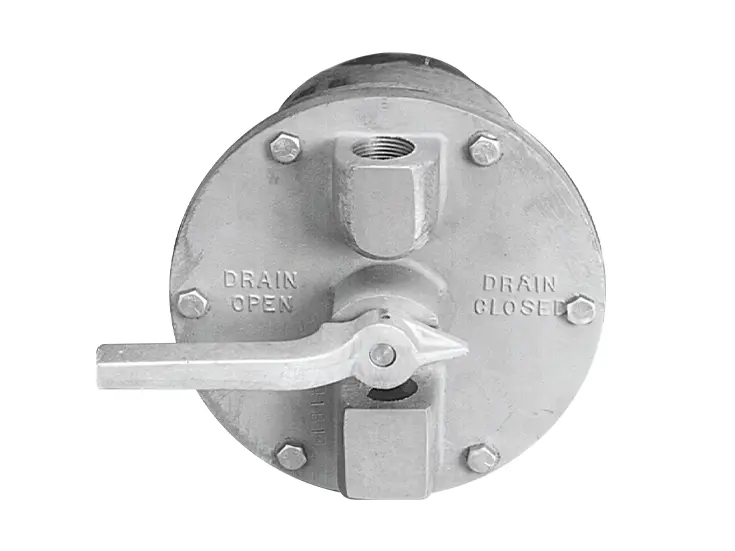

Designed for the manual collection and safe removal of condensate, the 246 Drip Trap is suitable for working pressures up to 5 psig (34.5 kPa).

How it works

A simple rotation of the 246-Series handle allows accumulated condensate in the drip trap reservoir to be drained manually. The disc position ensures that when the trap is draining, the inlet port is blocked. The disc, ports, and “O” ring seals are positioned to block gas before opening the drain outlet ensuring that gas does not escape.

Design Features

- Corrosion resistant aluminium

- 2.5 and 6 quart reservoir capacity

Downloadable Resources

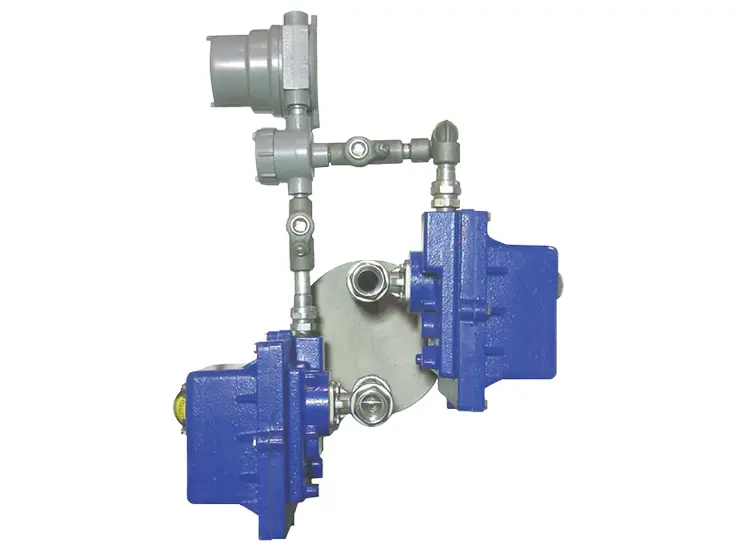

Designed for automatic and safe removal of condensate, the 246AT Drip Trap is ideal for installation in confined spaces with working pressures up to 5 psig (34.5 kPa). The unit comes equipped with a Class 1, Division 1 rated, high-torque reversible motor with a manual override. A UL approved control panel is available for remote operation of up to five electric actuated drip traps.

How it works

The electric actuator allows automatic fill and drain cycles of the drip trap at specified time intervals, within a minimum of 35 minute intervals.

Design Features

- Corrosion resistant aluminium construction

- 2.5 and 6 quart reservoir capacity

- Positive seal against gas escape

Downloadable Resources

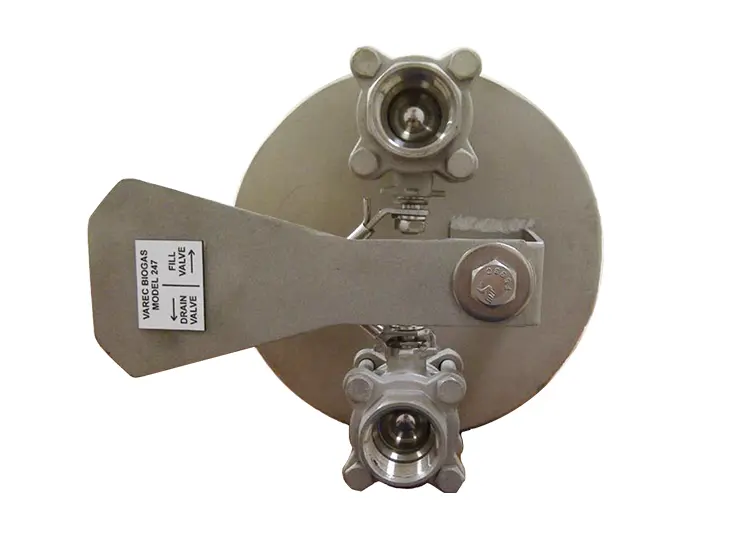

Designed for the manual and safe draining of accumulated condensate, the 247/ 247D Series Drip Traps are typically installed downstream of booster or compressors for systems with maximum working pressures of 100 psig (688 kPa).

The 247D has a dual-chamber design which provides a larger reservoir for condensate collection and is perfect for use with multistage compressors where the water must be drained from two chambers with different pressures.

How it works

Condensate accumulates in the drip trap reservoir and is drained manually by operating the valve handles. The double-seal ball plug valves and locking lever isolate the gas line connection before opening the drain port. When all accumulated condensate has been drained, the handles are returned to the “fill” position and locked in place.

Design Features

- Carbon Steel Body construction

- Ball Valves include Carbon Steel Body with SS Trim

- 4 and 6 Quart capacity reservoir (247)

- 10, 15 and 20 Quart capacity per chamber for low-profile dual chamber design (247D)

- All 316 SS construction option available

Downloadable Resources

The 247AT Drip Trap is designed for automatic and safe draining of accumulated condensate from high pressure gas piping. It is ideal for installation in confined spaces with maximum working pressures of 100 psig (688 kPa).

How it works

The 247AT Drip Trap is provided with an enclosed single timer that gives the flexibility to an operator to automatically FILL and DRAIN cycles, at a minimum of 35 minute intervals.

Design Features

- Carbon Steel Body construction

- Double-seal ball plug valves

- 4 quart capacity reservoir

- All 316 SS construction option available

Downloadable Resources

Designed to store a significant amount of condensate, the 248-Series Condensate Accumulator allows easy and reliable maintenance and operation.

How it works

The unit uses an internal drip leg and operates with a water seal which does not expose the tip of the drip leg. As condensate from the gas is diverted to the accumulator, the drip leg automatically drains the amount of condensate that is above the level of the water seal.

Design Features

- Carbon steel construction

- Epoxy coated internal and external rust inhibitive primer finish, stainless steel option

- Large condensate reservoir

- Optional sight glass and alarm switches