Safety Devices

Safety Devices, such as relief valves are essential to protect digesters and safely produce Biogas.

Digester relief valves are a safety equipment allowing an instant switch-over of the redundant pressure. They protect tanks from damages that can occur through over-pressure or excessive vacuum. Pressure relief systems should also be installed on intake lines of membrane gas holders.

The 2010B / 2020B Series Pressure and Vacuum Relief Valve are designed for use on atmospheric and low-pressure storage tanks. They protect tanks from damage or deformation, and minimises emissions to the environment, as well as loss of product due to evaporation.

How It Works

The “air-cushion” seating design keeps the valve tightly sealed until the pressure inside the tank approaches the valve setting. Once the pressure reaches the setting, the 2010B vents to atmosphere while the 2020B allows vapours to be piped away for recovery or destruction.

Design Features

- Available in 50 mm up to 300 mm sizes (2″ to 12″)

- Optional “All-Weather” Coating of Valve Seats and Guides

- Pressure Settings up to 2 psig (0.14 barg)

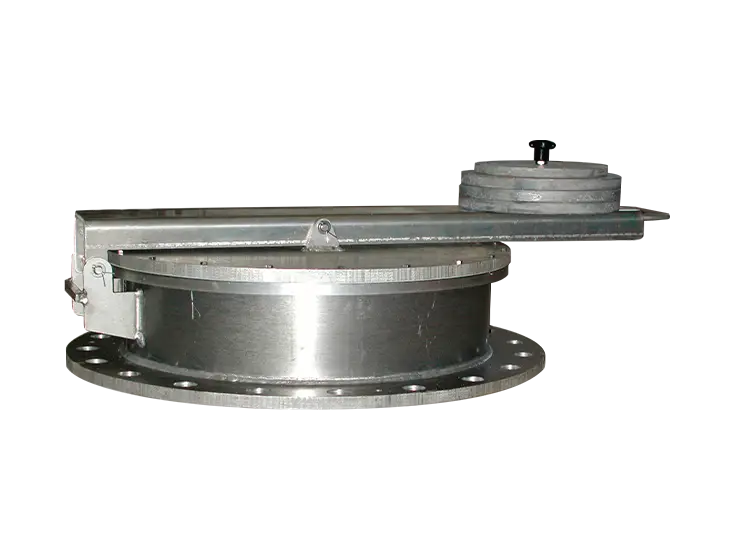

Designed to provide emergency pressure and/or vacuum relief in storage tanks and vessels, the 400W Series Emergency Relief Manhole Cover allows easy access for tank inspection and maintenance.

How It Works

The 400W Series works as a safety net, preventing explosions or implosions as pressure/ vacuum rises. If a set pressure is reached, the cover will relieve the overpressure by initially floating and then lifting from the seating area. Once the normal operating conditions are restored, the hinged design will allow for an automatic reseating of the cover. A spring-loaded vacuum relief valve is also provided for vacuum relief in the vessel.

Design Features

- Available in 254 mm (10”), 304.8 mm (12”), 406.4 mm (16”), 457.2 mm (18”), 508 mm (20”), 609.6 mm (24”), 762 mm (30”) and 914.4 mm (36”)

- Pressure and Vacuum combination available for 18″ and larger sizes only

- Self Draining

- Standard seating design ensures maximum leakage of less than 1 scfh at 90% of set pressure

- Factory tested and fully certified

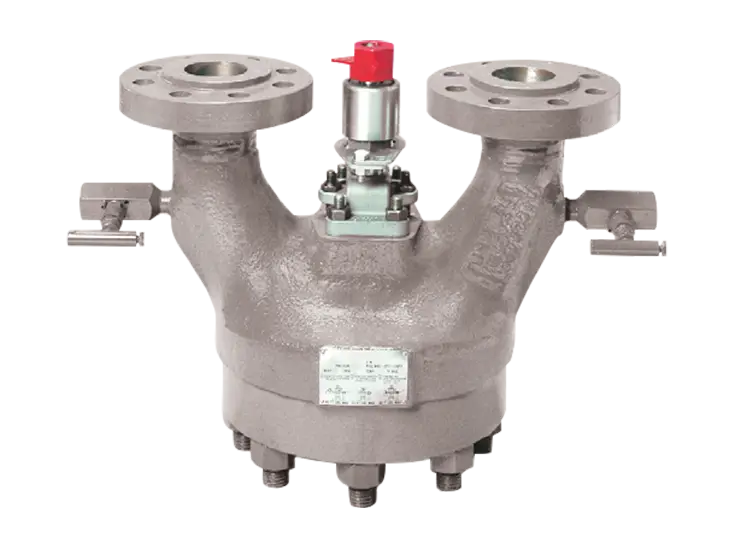

Designed to prevent the propagation of flame from external sources, the 5000/ 5010 Series Flame Arresters can be mounted up to 15 feet upstream of the ignition source, or 10 pipe diameters. The 5000 Series is intended for vertical installation while the 5010 Series can be installed in either horizontal or vertical positions.

How It Works

Flame propagation is stopped by absorbing and dissipating heat through the surface area of the bank sheets. Ignited vapours attempting to pass through the arrester is forced through small passages within the bank assembly. Heat is absorbed, lowering the temperature of the gas below its ignition point and quenching the flame.

Design Features

- Easy inspection and cleaning

- Constructed with heavy wall cast housing in 356 T6 aluminium, carbon steel, or 316 SS

- Up to four times NFA through bank

- Product UL approved

Downloadable Resources

Designed for low-pressure storage tank applications, the 5810B/5820B Series Relief Valve and Flame Arrester combine the high flow capacity of the 2010B / 2020B Series Pressure and Vacuum Relief Valve with the easy-to-maintain 5000 Series Flame Arrester.

How It Works

When the gas pressure or vacuum exceeds the systems’ setting, the pallet lifts to vent the excess pressure to the atmosphere. Air can also be drawn in to relieve an excess vacuum condition within the tank. The flame arrester prevents the propagation of flame and helps protect the tank from accidental ignition of vapours within the storage tank.

Downloadable Resources

Designed for low-pressure storage tank applications, the 5810B/5820B Series Relief Valve and Flame Arrester combine the high flow capacity of the 2010B / 2020B Series Pressure and Vacuum Relief Valve with the easy-to-maintain 5000 Series Flame Arrester.

How It Works

When the gas pressure or vacuum exceeds the systems’ setting, the pallet lifts to vent the excess pressure to the atmosphere. Air can also be drawn in to relieve an excess vacuum condition within the tank. The flame arrester prevents the propagation of flame and helps protect the tank from accidental ignition of vapours within the storage tank.

Design Features

- Oversized pressure and vacuum ports for maximised flow capacities

- Pressure and Vacuum available up to 1 PSIG

- “All-weather” coating option available for valve seats and guides